Manufacturing – Arihant ERP

Arihant AI | Manufacturing – Arihant ERP

Manufacturing - Arihant ERP

Manufacturing Work orders

Manage your products into assembly lines or manual assembly & Launch production of items needed in the final assembly of your products.

Repair orders

Manage repairs of items under warranty or as a service.

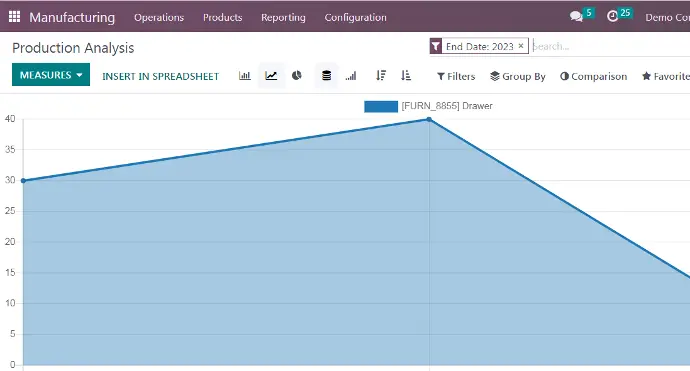

Overall Equipment Effectiveness

Analyze your work centers loads, the productivity losses and track your overall equipment effectiveness (OEE).

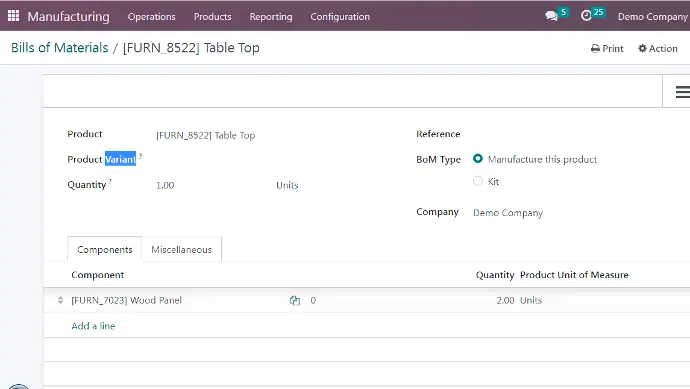

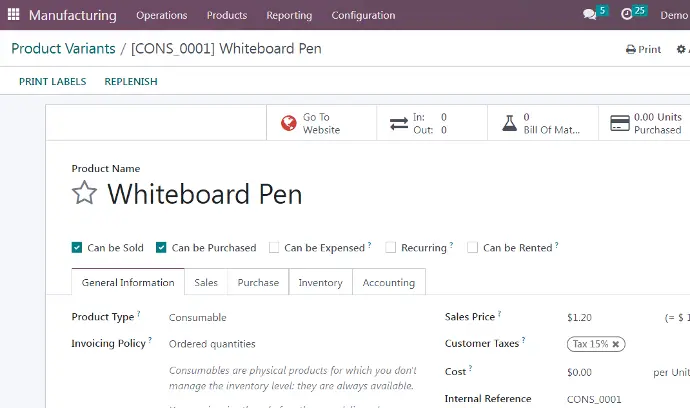

Multi-level Bill of Materials

Keep track of availability of items in stock and production time. Set a Bill of Materials within another in order to manufacture components of a product in another Bill of Materials.

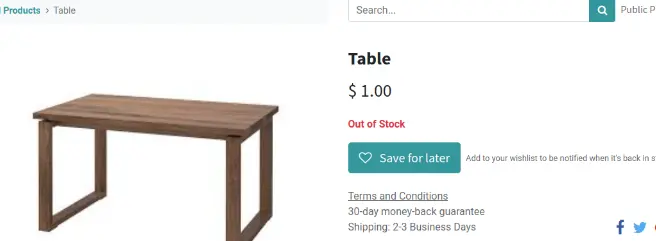

Manufacturing Kits

Using the Kit feature, your salesperson will be able to sell products that will be delivered as a set of components to assemble.

Record Production & Worksheets

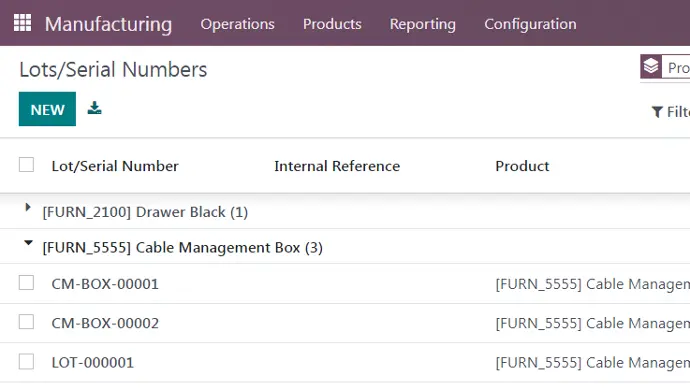

Register productions, scan products, lots or serial numbers. Display worksheets directly on the work center with instructions for the operator.

Preventive / Corrective Maintenance

Trigger maintenance requests automatically based on KPIs.

Traceability

Get a full upstream traceability report on the components used during the manufacturing process.

Advanced Routing

Create new routings for work orders in order to sequence your production depending on the routing used.

Process (Job) Costing

Track Material Cost / Labour Cost / Overhead Cost on Bill of Material or Manufacturing Order.

Bill of Material (BoM)

Define Bill of Material (BoM) formula with (2A + 3B ~ 4C +5D) approach for each product variant with all direct and indirect cost.

ARIHANT ERP - CLOUD BASED BUSINESS SOLUTIONS

Manufacturing Module Workflow

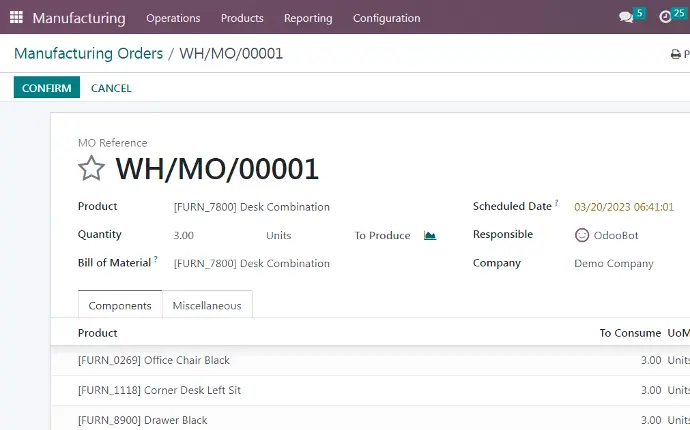

Create Manufacturing / Work Order from Sales Order directly

Wither Subcontract or Manufacture or Assemble products and record production in production location

Track Time spent on each manufacturing order / work order with specified work order instructions

Auto assign products to Pick or Pack operation depending on the push / pull rules

Get your stock back in your inventory

Analyze and track overall equipment effectiveness (OEE), Production Capacity, Production going in each phase and much more…

ARIHANT ERP